“Safety is a proxy for performance.”

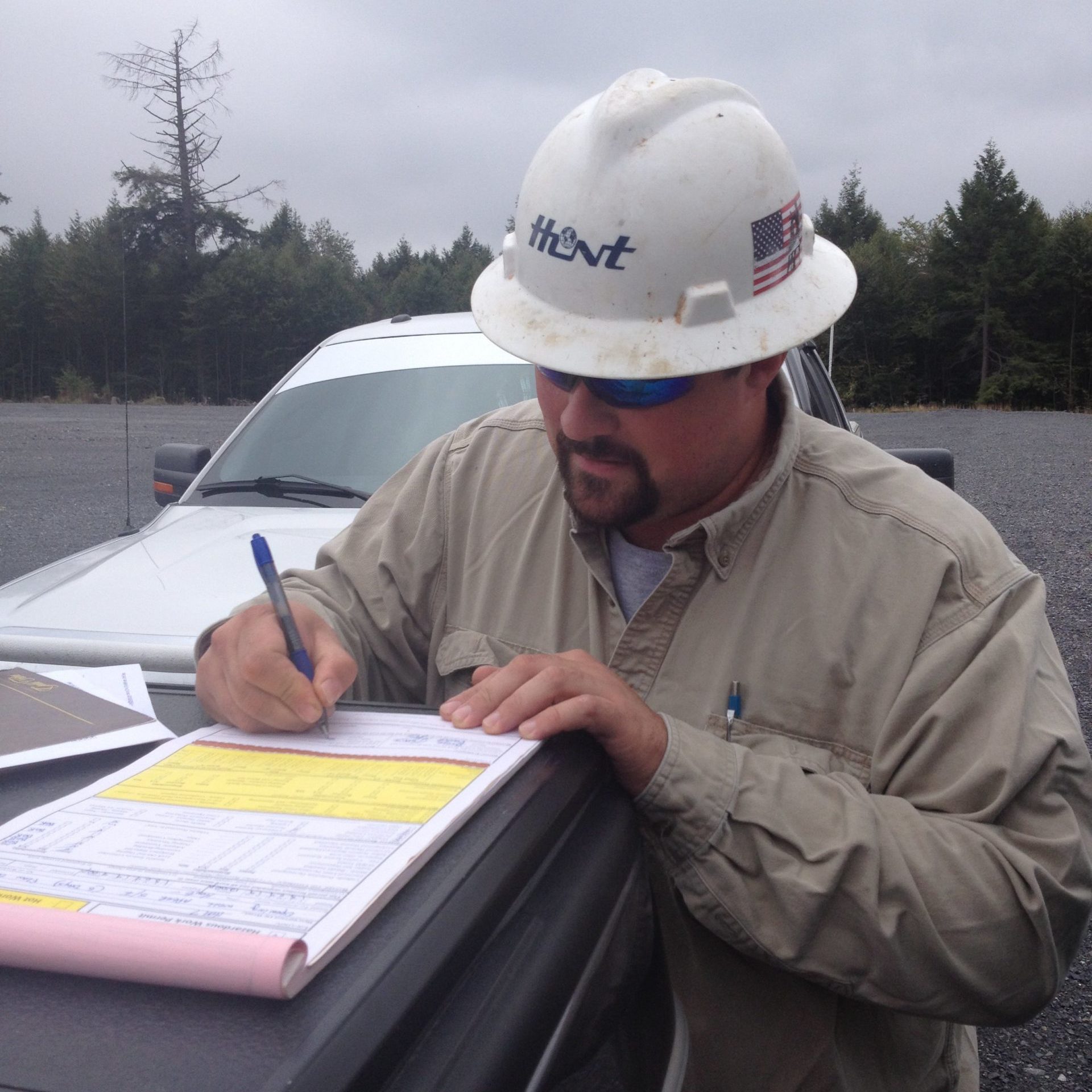

Mark GunninPresident, Hunt Energy

Construction of electric transmission tower in Texas

Our safety record is a reflection of our professionalism. Even in challenging areas of operation, Hunt teams who adhere to respect for one another, humility, and open communication create safer work environments. At Hunt, everyone is viewed as extended family, and our commitment to safety plays an even more important role. Put simply, we make a promise to each team member that everyone goes home safely, every day, to our utmost ability.

Our Safety Culture

Safety is a reflection of a well-run operation

Our safety culture is our defining attribute. We support this with tools, training, and initiatives that inform the safety culture at Hunt, but it is the individual decisions and ownership of these principles from our employees that encourage this culture to thrive.

- HSE Leadership

- Safety Performance

- Contractor Management

- Blue Jackets

- Annual Safety Picnics

- Safety Training

HSE Leadership Committee

The purpose of the Committee is to have all operational management collaborate and cooperate to ensure that Hunt’s commitment to Health, Safety, and the Environment (HSE) is supported and nurtured across all Hunt companies.

Primary goals include:

- Develop strategies to create a safe and healthy work environment

- Solve HSE problems and evaluate challenges

- Increase HSE Awareness and promote a strong safety culture

- Provide a link between our people in our communities (or in the field) and company leadership

Injury & Incident Rates

- From 2017 to 2023, Hunt decreased injury rates by approximately 50% with a focus on HSE planning

- The plans are designed to drive continuous improvement based on lessons learned and are endorsed by leadership

- Development and implementation of a behavior-based safety program includes daily Near Miss reporting and Unsafe Conditions reporting. Both are reinforced through positive recognition and continuous follow-up.

- Field-based personnel receive coaching and mentoring that leads them to own HSE initiatives in their areas

Total Recordable Incident Rate (TRIR) – work-related injury or illness that results in medical treatment, days away from work, restricted work, or position transfer

Lost Time Incident Rate (LTIR) – work-related injury or illness that results in days away from work

Days Away/Restricted or Transfer Rate (DART) – work-related injury or illness that results in days away from work, restricted work, or position transfer

TRIR, LTIR, and DART are calculated per 200,000 hours, equivalent to 100 full-time employees working a calendar year

Safety in Transportation

Transportation represents one of the biggest potential risks that impacts our operations. To keep our workforce safe on operational sites and in the office, we strive to minimize safety incidents while our employees are on the road.

- Preventable Vehicle Incident Rates (PVIR) are calculated based on the total preventable vehicle incidents in the workplace, per 1 million miles driven

- Hunt drivers logged more than 2 million miles in 2023 and achieved a PVIR of 0.9 in 2023, which is below the company benchmark of 1.28

- The PVIR rates have been reduced through a number of initiatives including driver training, monitoring harsh breaking activities in Peru, and improved vehicle maintenance and inspection routines in North America

Hunt emphasizes driver safety through:

- Defensive driving training

- Behind the wheel training

- Vehicle inspection programs

- Off-road/hazardous element training

Our vehicle fleet is subject to robust preventative maintenance programs that go beyond the manufacturer’s minimum standards.

Contractor Management

Many specialized jobs and large-scale projects require the use of contract labor and services, therefore, an important part of our overall safety and health program involves safety management for contractors.

During the bidding process, we perform HSE evaluations on all potential service providers that impact the end results. Contractors are expected to maintain a management system that meets or exceeds our corporate standards. Once on site, Hunt supervisors actively participate in operational and safety activities such as performing joint site inspections, reviewing permits, conducting job safety analyses and pre-job safety meetings. On-site contractor audits are performed to ensure compliance with HSE expectations, and any deviations are reviewed with the Contractor to determine a path forward for continuous improvement.

Blue Jackets

As part of our commitment to emergency management, Hunt established and trained a dedicated group of employee first responders to assist with potential emergencies at all Hunt office locations.

Blue Jackets serve as first responders during emergencies and take the lead in evacuation exercises, receive emergency response training, that interfaces with outside emergency responders, as well as training to provide key information to employees. Hunt Blue Jackets are First Aid/CPR certified.

The Company is committed to the Blue Jacket program and provides continuous training and other incentives to volunteers.

Initially, the Blue Jacket program focused on the Dallas campus but has since been adopted in Hunt offices around the world.

Annual Safety Picnics

Safety picnics are held each year in areas that operate across the Company and serve as an opportunity for employees and their families to listen and share safety messages.

The Hunt executive leadership team participates and communicates our commitment to safety, performance highlights, and announces any new initiatives.

Safety Training

Our commitment to safety is an expectation for all employees and is reinforced through training across the company.

An employee training matrix has been developed based on risk assessment results and is a major leading indicator KPI for all employees. The matrix contains three tiers of training based on a risk assessment of the work to be performed as well as regulatory training requirements and Hunt best practices. The training requirements and frequency for each level (Administrative, Technical and Hazardous Areas) are clearly defined and based on employee position. The course curriculum is made up of classroom, web-based, and hands-on training.

Our Safety Framework

Asset Integrity

Hunt effectively manages its assets to gain maximum value, profitability, and returns while safeguarding personnel, the community, and the environment.

Our Asset Integrity Management program incorporates design, maintenance, inspection, process, operations, and management concepts, since all of these disciplines impact the integrity of infrastructure and equipment.

Hunt uses technologies, such as optical gas imaging cameras, at many production and process facilities in order to monitor the integrity of our operations. When we identify risks, we implement appropriate preventive measures for equipment, processes, and people.

Timely Observation, Effective Corrective Action

At Hunt, we believe if you see something, say something.

Stop Work Authority is a program embedded into Hunt’s safety management culture. It provides any employee, contractor, or visitor with the ability to stop the work if they see something unsafe.

Employees and contractors are required to report all incidents involving injury, environmental impact, property loss, or near-miss events. Incident Reporting and Investigation is submitted to our Management System (MS) and is standardized across the organization as part of the ongoing MS development and rollout.

We strongly encourage fact-finding, not fault-finding. Employees are trained annually in Root Cause Analysis techniques which are conducted for all incidents. Safety observation and near-miss programs are utilized to ensure hazards are found and fixed before there is a problem and that lessons learned are shared throughout the organization timely.

Process Safety Management (PSM)

Hunt has established a comprehensive PSM program that integrates technologies, procedures, and management practices.

Performance is measured using key performance indicators that align with industry recommended practices.

Process Safety Management (PSM) applies design best practices to properly install, operate, and maintain covered process equipment so that workers, neighbors and the environment are protected from the unintentional releases of highly hazardous substances in the field.

We are committed to continuously strengthening our PSM system. By fostering a collaborative and agile culture, we conduct multidisciplinary sessions to analyze risks in critical daily activities. This proactive approach enables us to make swift, informed decisions, effectively mitigating hazardous situations and minimizing risks.